Operational resilience

Prepare for unforeseen challenges, maintain seamless operations, and protect your reputation in times of crisis.

Operational resilience vs organizational resilience

Operational resilience focuses on maintaining critical functions during disruptions, addressing immediate, day-to-day challenges. In contrast, organizational resilience takes a broader view, encompassing strategy, culture, and the ability to adapt and thrive in the face of change. Together, these concepts blend continuity with long-term adaptability, creating a robust foundation for sustainable success.

The Everbridge High Velocity CEM™ platform, Everbridge 360, empowers organizations to proactively improve their operational and organizational resilience. Powered by Purpose-built AI, Everbridge 360 ensures operational continuity and turns risk management into a competitive advantage in an increasingly complex and disruptive world.

Common operational resilience challenges

Regulatory compliance

Keeping up with evolving regulations and ensuring compliance can be resource intensive and complex.

Complexity of systems

Organizations rely on complex, interconnected systems, making it difficult to identify and manage potential vulnerabilities.

Main regulations for operational resilience globally

European Union

DORA sets rules for EU financial entities on ICT risk management, incident reporting, resilience testing, and third-party risk monitoring. It also mandates reporting major ICT incidents to authorities to ensure operational resilience.

United Kingdom

The UK’s PRA’s operational resilience rules require firms to identify important services, set impact tolerances, and ensure disruptions stay within these limits through testing and reporting.

Australia

Australia’s APRA Prudential Standard CPS 230 mandates companies to maintain a risk management framework, including governance, risk assessments, internal controls, and business continuity planning.

Benefits

- Enhanced communication: share critical data with executives, employees, stakeholders and external parties.

- Improved incident monitoring: by offering early and detailed insights on how and what threats will impact your operations, helping you stay ahead of potential disruptions.

- Coordinated response: improve operational resilience with swift and efficient coordination of resources.

- Manage third-party risk: link data dependencies across services and locations for clear visibility into what’s impacting your organization.

- Enhanced preparedness: conduct scenario testing, set impact tolerances, automate communications and post-event analysis to enhance incident response time.

Features

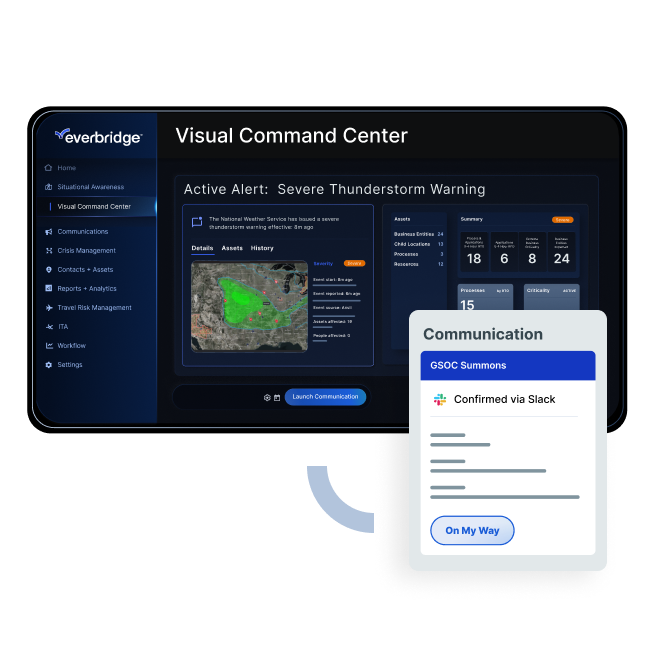

- Automated alerts: ensure timely notifications are sent to the right people at the right time, reducing response times during an event.

- Scenario testing: conduct comprehensive tabletop exercises and scenario testing to gain valuable insights.

- Data dependency linkage: gain unparalleled monitoring capabilities for your ICT third-parties by seamlessly linking data dependencies across services, providers, applications, locations, and business processes.

- User-friendly interface: which offers intuitive shareable dashboards, impact trackers, reports, and surveys.

- Centralized hub: store and regularly review plans to help with managing, and responding to critical incidents.

Solution

The Everbridge High Velocity CEM platform, Everbridge 360, helps you manage your operational resilience strategies by identifying key information assets and ICT-supported functions. Everbridge 360 can help protect and prevent events from impacting business functions, providing early threat identification and scenario testing.

BC in the Cloud® helps WEX, Inc. achieve operational resilience

With limited capabilities from its existing business continuity and disaster recovery software, WEX began researching alternative solutions in 2017. The rapidly growing company needed a system that was flexible, scalable, provided greater reporting capabilities, and offered a positive end-user experience.

WEX narrowed its initial research of dozens of vendors down to five companies, then to three, and ultimately selected BC in the Cloud®.

How it works

Everbridge helps your organization identify critical business processes and the risks that could leave it vulnerable. Once assessments are done, Everbridge is used to create recovery plans, test the plans, and respond during a crisis, and then report and improve. It is scalable to accommodate the needs of both large and small organizations.

Counter risks effectively

Everbridge Risk Intelligence offers comprehensive global risk insights to empower your decision-making process. This video highlights how actionable data can lead to lifesaving actions, ensuring your operations continue seamlessly. With our dedicated Risk Intelligence Center available 24/7, 365, we provide the precision risk intelligence necessary to keep you informed and prepared.

Outcome

Using Everbridge can help you respond and recover from critical incidents. Powered by Purpose-built AI, it can provide you with a greater understanding of what services and processes impact critical functions within your business. With improved threat detection, scenario testing, enhanced coordination, and sharing of information, you can reduce response times and improve the overall resiliency of your operations.

Achieve operational resilience in a regulated world

Building true operational resilience has never been more critical, especially in the face of regulations like DORA and the Bank of England’s operational resilience framework

Everbridge named a Leader in The Forrester Wave™: Critical Event Management, Q4 2023

According to a Forrester TEI Study 20231, organizations using the Everbridge CEM platform demonstrated improved capabilities to respond to and contain disruptions, effectively protecting employees, assets, and business processes. Over three years, the quantified benefits are:

- Businesses saved up to $3 million in efficiency gains by reacting quickly to unplanned events.

- Intelligent alerting helped organizations save up to $2 million by improving workflows and addressing IT issues efficiently.

- Enhanced coordination and 24/7 support allowed security teams to save $1.5 million.

Industry solutions for operational resilience

Financial services

For financial organizations, Everbridge enhances operational resilience by coordinating regulatory compliance and empowering resilience. By utilizing advanced communications, threat detection, and real-time alerts, financial institutions can improve response times and mitigate risks, helping to improve overall resiliency.

Energy and utilities

Energy and utility companies can improve their operational resilience by implementing the Everbridge platform to identify key assets, establish safeguards to protect ICT systems, and leverage better coordination and response once a threat is detected helping the organization become more resilient.

Telcomms

For Telecom companies, Everbridge significantly enhances operational resilience by bolstering planning, identification, detection, and response and recovery for ICT-related incidents. By enabling real-time threat detection, seamless coordination, effortless information sharing, and comprehensive tabletop exercises, companies can swiftly coordinate responses and disseminate critical information. These strategies help safeguard key services and systems, reduce downtime, and uphold service commitments.

Additional resources

Understanding DORA: How to operationalize digital resilience

In an interconnected world, digital resilience is crucial for navigating crises and safeguarding financial and security assets. The European Union (EU), comprising 27 countries and 450 million people, recognizes the significance of digital resilience and has introduced regulatory mandates.

Operationalizing resilience for your organization

Effective risk intelligence is the cornerstone of any resilient organization. It involves understanding and monitoring the potential risks that could impact an organization and its employees. This goes beyond immediate concerns and involves looking at the bigger picture.

The ultimate operational resilience handbook

A practical guide for risk professionals to manage the multiple dimensions of operational resilience.

Operational resilience FAQs

Operational resilience refers to an organization’s ability to anticipate, prepare for, respond to, and recover from potential disruptions while maintaining critical operations. It ensures the continuity of services even in the face of unforeseen challenges like cyberattacks, natural disasters, or supply chain interruptions.

Operational resilience is critical for minimizing downtime, safeguarding sensitive data, maintaining customer trust, and complying with regulations. It ensures essential services remain available during a crisis, protecting both people and the organization’s reputation.

Organizations often face challenges such as managing complex systems and understanding the related dependencies, addressing growing threats (both physical and digital), and keeping up with regulatory compliance and business continuity plans to name a few.

Operational resilience offers numerous benefits, including reduced downtime, stronger customer loyalty, enhanced and operationalized regulatory compliance, and better risk management. It also helps businesses adapt to disruptions more quickly and minimize financial losses, ensuring long-term success and stability.

Organizations should prioritize doing an assessment of services and business processes to capture critical business processes and risks that could leave the company exposed. Once assessments are done, create recovery plans, test the plans, report, and improve.